Flangeless Piping Solution for Fugitive Emissions and External Corrosion

OVERVIEW

A state-of-the-art chemical processing plant operating in Southern Louisiana used a lined steel piping system with flange connections to handle ethylene dichloride (EDC). Plant operators handling the toxic, fuming EDC (also commonly known as dichloroethane DCE) must practice extreme caution and rigorously monitor the condition of their systems, especially pipe joints and flange connections. This lined steel system required an expensive testing and maintenance regimen, performed multiple times each year by an outside contractor, to monitor fugitive emissions from each of the many flange connections and apply sealing paint to address external corrosion.

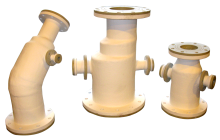

The plant operator chose to replace the lined steel with a flangeless Simtech ArmorTech® system featuring Kynar®740 PVDF reinforced with a vinyl ester fiberglass overwrap. Under these conditions of service, ArmorTech provides a longer service life than lined steel, is much lighter and installs easily using butt-fusion and simple field wrap kits. By removing flange connections from their system, the plant owner eliminated almost all potential leak paths and fugitive emissions problems, improved jobsite safety and saved money on monitoring and maintenance.

CUSTOMER / LOCATION

Chemical Processing Plant, Southern Louisiana